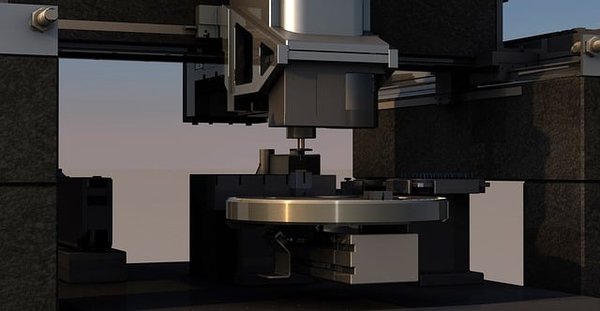

The Essilor Kappa CTD M15 lens edger stands out for its precise edging and low cycle count, promising reliable performance and extended lifespan. Designed to meet high standards, it offers compatibility with a range of lenses and accessories, making it a versatile choice for optical professionals seeking both quality and efficiency in lens finishing.

Essilor Kappa CTD M15 Lens Edger: Key Features and Industry Advantages

Engineered for precision and speed, the Essilor Kappa CTD M15 is packed with advanced innovations that set a new benchmark for optical lab equipment—making it easy for professionals to buy Essilor Kappa CTD M15 Lens Edger online for dependable results. Its core functions include seamless drilling, frame modification, 3D numerical chamfering, and template-free lens edging. The system's patented dual-face scanning ensures every lens—thin or specialty—receives exact shaping, while automatic wheel cleaning and digital controls simplify everyday operation.

This user-friendly lens edger reduces manual intervention, drastically minimizing human error and accelerating the lens edging process. Consistent quality and repeatability become standard, even when handling complex or delicate lenses. Multi-curve edging, customizable chamfering, and a broad range of compatible materials—from organic to polycarbonate or Trivex—bring true flexibility for bespoke and progressive lens work.

Its integration into global optical labs makes it a trusted device among professionals seeking to meet 2025’s demands for efficiency and high-quality eyewear. The M15’s robust digital enhancements, ergonomic design, and comprehensive calibration support create smooth workflows, boosting productivity without compromising on precision.

Specifications, Compatibility, and Usage Guidance

Detailed specifications: dimensions, power supply, noise level, water consumption

The ESSILOR Kappa CTD M15 demonstrates robust optical lab equipment standards through its compact dimensions (L535 x D410 x H568 mm) and its compatibility with both 230 V/50 Hz and 115 V/60 Hz power supplies. This high-speed lens edger ensures operational efficiency while maintaining a noise level of 79 dBA. Its water consumption averages 5 liters per minute—an industry-appropriate figure supporting continuous lens beveling capabilities and maintaining lens measurement accuracy in demanding settings.

Supported lens materials and eyeglass frame compatibility

Operators benefit from wide eyeglass frame compatibility, processing organic, polycarbonate, mineral, and Trivex lenses. The ESSILOR Kappa CTD M15’s lens finishing solutions enable various finishes such as bevel, flat, and groove, leveraging precision cutting. The machine’s architecture accommodates lens edge aesthetics without compromising measurement precision. Frame coping techniques adapt accurately, and the system accommodates large and small frames, enhancing flexibility for customized eyeglass lenses.

Usage guidance: operator workflow, lens blocking accuracy, safety, and maintenance recommendations

An intuitive lens blocking system heightens lens blocking accuracy and consistency, reducing manual errors in customized eyeglass lens production. To promote safety, this optical lab equipment supports clear workflows and provides straightforward operational and maintenance routines. Regular calibration and wheel cleaning cycles are recommended. Adhering to the lens edger operational guide ensures stable performance, helping extend equipment life and uphold precise lens edge aesthetics.

Comparative Assessment, Maintenance, and Market Insights

Comparison with alternative lens edgers: Essilor Neksia, Essilor Gamma, Kappa M1, M2, M6

The Essilor Kappa CTD M15 lens edger distinguishes itself with advanced lens customization features and robust edge quality control. Compared to the Essilor Neksia, Essilor Gamma, and earlier Kappa models (M1, M2, M6), the M15 enhances lens edge smoothing and introduces more consistent lens edging results. Its comprehensive automation supports a broader array of lens shapes and materials, meeting evolving optical manufacturing trends and improving overall optical lab best practices. Notably, its design safeguards lens edge durability, especially useful in busy labs aiming to minimize errors and speed up production while still enabling affordable lens edger solutions.

Maintenance, calibration, spare parts, and service availability

Maintenance and repair and service options for the Kappa CTD M15 are streamlined through modular spare parts, including calibration units and edge quality control gauges. Professional support ensures the machine’s durable lens edging machines deliver optimal performance. Detailed operator manuals and available lens edger safety features simplify routine cleaning and recalibration, facilitating ongoing compliance with optical lab best practices. Enabling swift troubleshooting and minimizing downtime, these direct measures play a crucial role in reducing turnaround times.

Pricing, warranty, vendor information, and operational cost considerations

Current average market pricing for the Kappa CTD M15 gravitates towards affordability within its category of durable lens edging machines. The standard edger warranty info typically covers a six-month period, with repair and service options extending the equipment’s operational life. Reliable vendor guidance and transparent operational cost breakdowns empower buyers to select affordable lens edger solutions that align with their workflow and future-proof their practice for new optical manufacturing trends.